Hydraulic systems are critical components in industrial machinery, construction equipment, and manufacturing operations. Their ability to deliver high power through compact designs makes them indispensable. However, like any mechanical system, they require consistent care to avoid premature failures, costly downtime, and unsafe working conditions.

Professional hydraulic cylinder repairservices play a vital role in ensuring that hydraulic systems remain in peak condition. Beyond reactive repairs, preventive maintenance practices keep equipment running efficiently, reduce breakdowns, and extend overall lifespan. This article explores key strategies professionals use to protect hydraulic systems and keep them in the best shape.

Regular Fluid Inspection and Replacement

The heart of any hydraulic system is its fluid, which acts as both a power transmitter and a lubricant. Professionals focus on checking fluid levels, viscosity, and cleanliness to ensure optimal performance. Contaminated fluid can accelerate wear on pumps, valves, and cylinders, which leads to serious damage.

Routine fluid replacement also prevents sludge buildup and overheating issues. Experts drain and flush systems when necessary, then refill them with the correct grade of hydraulic fluid. This step keeps components lubricated, minimizes friction, and supports smooth, reliable operations.

Filter Maintenance for Clean Operation

Filters prevent dirt and debris from entering sensitive components. Over time, these filters collect particles that can restrict flow and reduce system efficiency. Professionals inspect filters on a schedule, replacing them before clogging leads to cavitation or pump strain.

It is best to maintain clean filters also prevents contamination before it reaches cylinders, which can cause scoring and seal damage. This simple step reduces the likelihood of costly repairs and ensures consistent system pressure. Clean filters also improve overall system efficiency and extend the lifespan of other critical components.

Hose and Fitting Inspections

Hoses and fittings endure significant pressure and can become weak over time. Experts look for cracks, bulges, and leaks during inspections. It is best to detect wear early to prevent catastrophic failures that could cause downtime or safety hazards. Routine inspections also help maintain consistent pressure flow across the entire system.

When issues are found, professionals replace defective hoses with ones rated for the correct pressure and temperature. Properly tightened fittings prevent leaks and maintain system integrity, allowing equipment to run safely and efficiently. Using manufacturer-approved components ensures compatibility and long-term reliability.

Cylinder Seal and Rod Care

Hydraulic cylinders rely on seals and rods to operate without fluid leaks. Professionals check seals for wear, hardening, or cracks. Early replacement of worn seals prevents fluid loss and pressure drop. This proactive approach preserves consistent hydraulic performance.

Rod surfaces are inspected for scoring, rust, or pitting. A damaged rod can quickly destroy seals and reduce performance. Proper rod care ensures cylinders retain power and accuracy under heavy loads. Periodic polishing or refinishing of rods can further extend their service life.

System Pressure and Temperature Monitoring

Maintaining pressure within manufacturer specifications is critical to hydraulic system longevity. Experts use gauges to verify operating pressure and detect abnormalities before failures occur. Consistent operation at too high or too low pressure can damage pumps and actuators. Regular calibration of gauges ensures accurate readings and dependable monitoring.

Temperature control is equally important, as overheating can degrade hydraulic fluid and seals. Professionals ensure cooling systems, such as heat exchangers or fans, function correctly to keep operating temperatures stable. Proper ventilation around equipment also helps dissipate heat effectively.

Scheduled Preventive Maintenance Programs

Rather than waiting for a breakdown, professionals establish routine maintenance schedules. These programs include regular inspections, fluid analysis, and component servicing. Predictable maintenance minimizes unplanned downtime and extends equipment life. This systematic approach ensures equipment reliability year-round.

Documentation of each inspection helps track system health over time. Experts use this data to spot recurring issues and make adjustments that optimize performance and prevent repeat failures. Keeping detailed records also helps plan future part replacements and budgeting.

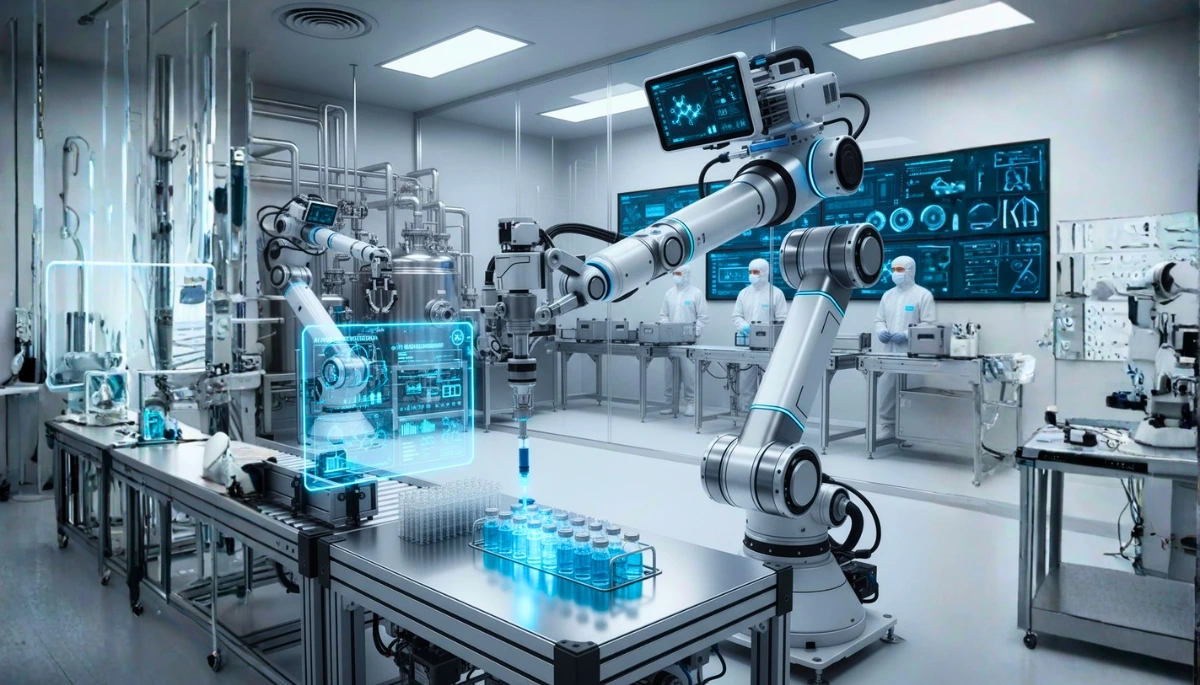

Leverage Professional Expertise

Relying on skilled technicians ensures hydraulic systems are maintained to the highest standards. Professionals use precision tools and diagnostic equipment to detect problems invisible to the naked eye. Their training allows them to work efficiently and restore systems to full capacity.

Working with experienced service providers also means access to quality parts and reliable repairs. Whether troubleshooting pressure loss or replacing a cylinder, experts deliver results that keep operations running smoothly. Their timely intervention minimizes downtime and helps maintain productivity.

Preventive maintenance is the key to maximizing the lifespan of hydraulic systems. From fluid care and filter changes to monitoring pressure and temperature, each step contributes to overall reliability. Relying on professional hydraulic cylinder repair services ensures that inspections, repairs, and adjustments are done correctly. With the expertise of trained professionals, businesses benefit from reduced downtime, lower repair costs, and safer operations. Consistent care leads to long-lasting equipment performance and improved productivity.