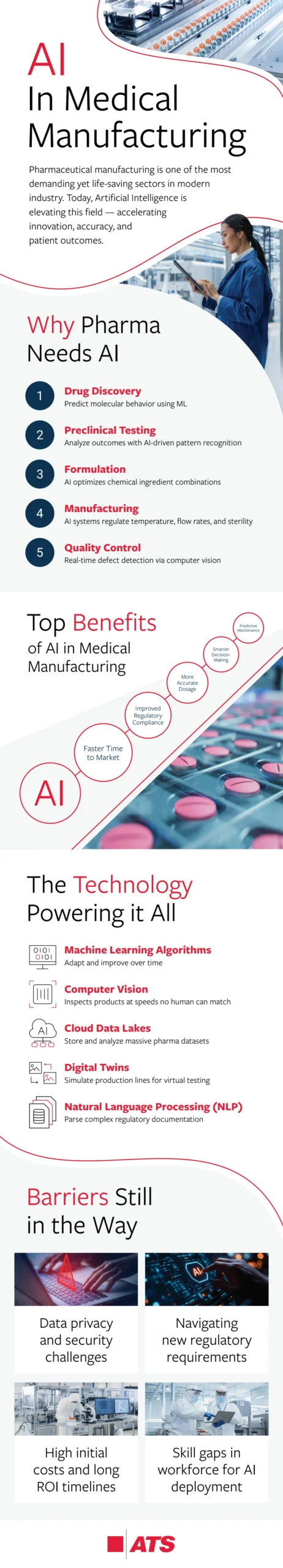

Artificial intelligence isn’t revolutionizing pharmaceutical manufacturing with loud disruption — it’s doing so quietly, with steady progress that’s transforming how precision and consistency are achieved. In a space where every process must meet rigorous standards, AI is becoming an indispensable tool for navigating complexity and reducing error.

Production in this industry is never straightforward. From fluctuating raw materials to strict environmental controls, there are countless opportunities for variability. AI helps bring more stability into that equation, supporting human teams by delivering timely insights and fine-tuned automation.

From Reactive to Proactive: How AI Enhances Efficiency

Traditional automation runs on static instructions. AI, by contrast, adapts. With each new batch of data, machine learning algorithms improve, allowing systems to detect subtle shifts before they become problems.

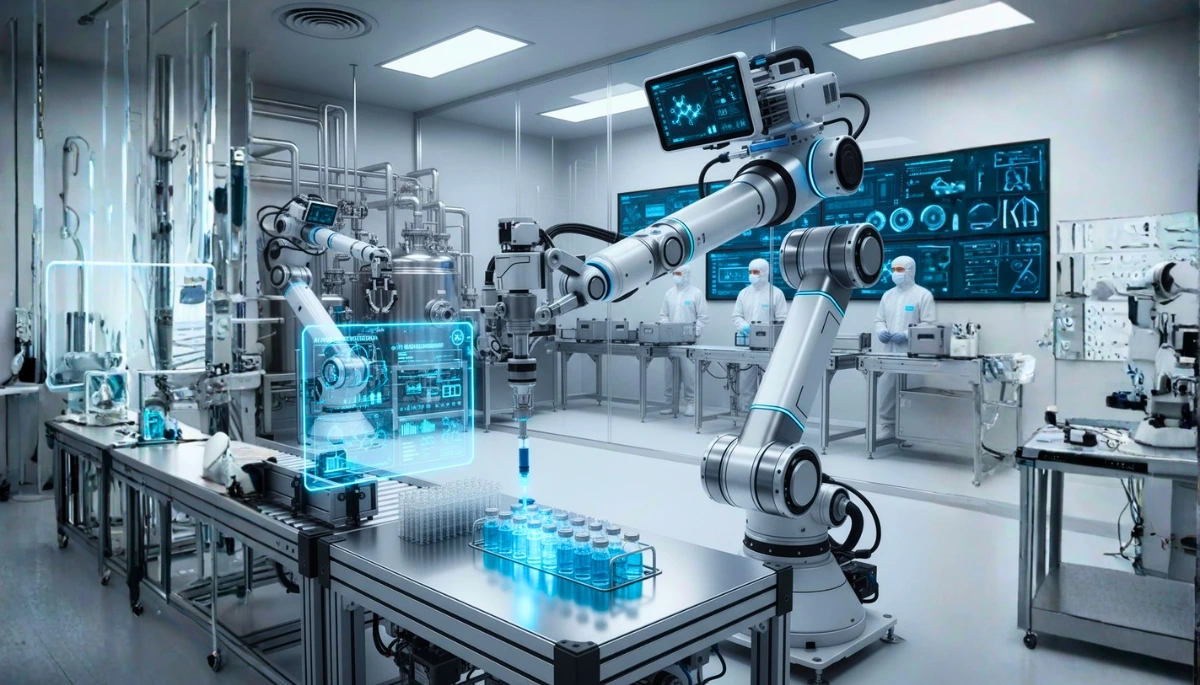

For example, early indicators of machine fatigue can trigger alerts for maintenance well before a breakdown. Similarly, if conditions on the production line begin to veer off-course, AI can recalibrate operations in real time. These adaptive responses mean fewer interruptions, better use of materials, and more reliable production quality.

Even outside of manufacturing lines, AI is proving its value in logistics. Real-time demand forecasts, predictive stock level monitoring, and intelligent supply chain adjustments are helping manufacturers stay nimble in a volatile market.

Modernizing Without Compromising Compliance

One of the biggest hurdles for pharmaceutical companies adopting new technologies is regulatory pressure. Compliance isn’t optional, and innovation must fit within that framework.

AI helps companies thread that needle. Natural language processing tools can comb through complex regulatory documents quickly, helping teams interpret requirements with less manual effort. Automated recordkeeping and data tracking also ensure that every decision and adjustment is documented, creating full transparency for auditors and stakeholders.

Instead of slowing innovation, AI helps streamline it — reducing the friction between progress and oversight.

A Smarter Foundation for What Comes Next

AI isn’t just a productivity tool. It’s becoming the infrastructure on which modern pharmaceutical manufacturing is built. It enables more resilient systems, improves traceability, and opens the door for innovation that doesn’t come at the cost of quality or safety.

In the long run, it’s not about machines replacing people. It’s about giving teams better tools to make decisions, respond quickly, and meet the growing demands of the healthcare industry with greater confidence.

For additional insight into how AI is redefining standards in pharmaceutical production, explore the visual guide accompanying this article from Advanced Technology Services, provider of predictive maintenance services.